Safety is a top priority in any workplace, and factories are no exception. Factory safety signage ensures all safety protocols are communicated clearly, to reduce risk and ensure accident prevention. Clear, visible signage throughout your facility isn’t only wise, it’s a legal obligation.

If you’re managing a manufacturing facility, ensuring the right safety signage in place is essential to protecting employees, maintaining productivity, and remaining compliant with regulations. Safety signage can prevent costly accidents, reduce the risk of injury, put workers at ease in their surroundings, and even increase morale.

Yodeck’s solution for manufacturing digital signage can make safety messages more visible and memorable. With digital signs, you can turbocharge the benefits of safety signage in your factory while reaping the rewards of better communication overall.

With this blog post, we’ll cover the fundamentals of factory safety signage, including the different types of signs and how you can ensure the visibility of safety communications. Read on to find out how to ensure your workplace safety signs work for you.

What is Factory Signage and Why Do You Need It?

Factory safety signage alerts employees to risks within the workplace and reminds them of safety procedures that reduce these risks.

In the UK, HSE regulations require manufacturing facilities to display a warehouse sign if there’s no other way to avoid or control a significant risk at their facility. The US has similar requirements, with the Occupational Safety and Health Administration (OSHA) outlining specific requirements for safety signs in factories, warehouses, and other manufacturing facilities.

Compliance with these regulations reduces fatalities, and non-fatal workplace injuries and improves the well-being and productivity of employees. For example, according to one study , digital signage can reduce the risk of injury at work by 20%.

The proper safety signs in the right places reduce workplace injuries and fatalities by alerting employees to risks, reminding them of safety precautions , and communicating the seriousness of safety procedures.

Let’s explore what you need in more detail.

What Safety Signage Do Factories Need?

UK rules on factory safety signs differ slightly from those in the US. While there are 5 main types of safety signs required by UK manufacturers, US counterparts have 4 safety sign categories to consider.

5 types of Factory Safety Signs for UK Businesses

Prohibitory signs. These simple signs have black and white pictures with a red circle surrounding them and a diagonal line running through the centre. These signs give specific instructions prohibiting specific actions, such as “No Naked Flames”.

Warning signs. Warning signs always have a yellow background with black writing and pictures. They’re designed to alert employees, visitors and customers to possible risks in your factory.

Mandatory signs. These round “must do” signs let workers know they should be wearing protective gear or behaving in a specific way to avoid harm. These signs have a white image on a blue background.

Safety signs. Safety first signs aren’t only about risks—they can also show employees where safe areas and safety equipment are. These types of signs have white images on green backgrounds. They identify fire exits, muster points, and first aid equipment.

Fire safety signs. These signs feature a white symbol on a red background and indicate the locations of fire-fighting equipment or an emergency exit sign.

4 types of Factory Safety Signs for US manufacturers

US regulations categorize factory safety signs a little differently. The four fundamental safety signs that need to be considered are:

Caution signs. Used to warn of a potential hazard and unsafe practices, caution signs have a yellow background with black lettering and images. Specific standardized symbols are used too.

Safety instruction signs. These signs give general instructions and suggest relevant safety measures that need to be taken in specific areas. Caution sign words, such as “Warning” or “Danger” need to be easily readable from five feet away or more, and depending on the nature of the safety risk, other specific design requirements may be needed.

Danger sign. Red, black and white are the colors used to identify specific dangers. They’re used for major hazard situations and can be illuminated to make them easily stand out.

Biological hazard signs. If your factory uses chemicals, experimental animals, or equipment, you’ll need factory safety signs to warn of the dangers associated with them. They indicate a specific risk and sometimes include instructions on how that risk should be handled.

Of course, the signs you choose must be relevant to your facility. The types of personal protective equipment, evacuation procedures, and hygiene protocols will naturally differ between businesses and even between the sites of one business’s operations.

As such, they should be tailored to your specific requirements and the requirements of each factory location. Manufacturing information displays help to make this easy.

Of course, the signs you choose must be relevant to your facility. The types of personal protective equipment, evacuation procedures, and hygiene protocols will naturally differ between businesses and even between the sites of one business’s operations.

As such, they should be tailored to your specific requirements and the requirements of each factory location. Manufacturing information displays help to make this easy.

How Digital Signage Can Make Your Safety Information More Effective

Safety signs are designed to draw attention to hazards and should be placed with this in mind. They need to be easily seen and close to the hazard they’re identifying. However, too many safety signs in a single area can be confusing.

That’s where digital signs come in. They’re an ideal solution because they enable multiple signs to play from one screen without conflicting or overloading the viewer with too much information.

Picture it. You can time safety messages to scroll across a single screen so they complement each other. That means reminders to wear safety clothing, maintain a safe distance from equipment, or keep specific areas sanitized can all be displayed on production display boards without causing confusion.

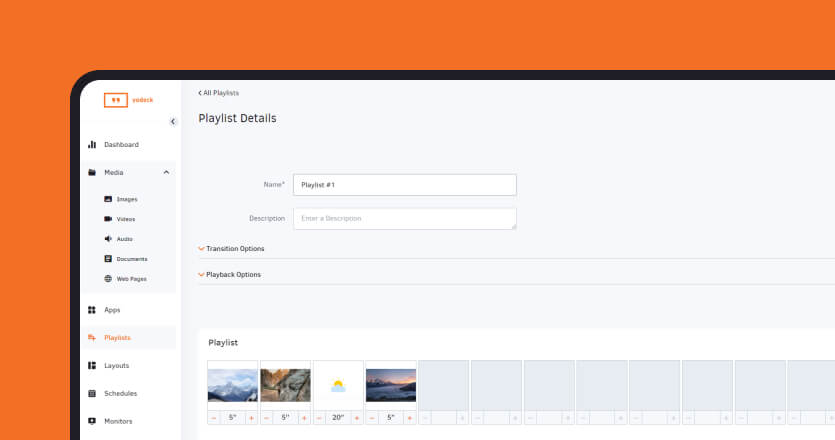

All this safety guidance and more can be displayed with Yodeck’s plug-and-play software. All you need to do is set up a playlist with all the information you need.

4 Steps to Get the Most Out of Your Digital Safety Signage

Although there are specific rules around safety signs, there is plenty of scope for managers to tailor their signs to suit individual workplaces. Sign standards shouldn’t stop you from getting a little creative with your messaging to improve workplace safety.

Consider these safety sign fundamentals when selecting signage for your factory:

Design safety signs with visual content

The way safety signs are designed has a big impact on how well they’re understood and remembered.

The majority of the information our brains take in is visual. In fact, visual data—that’s pictures, graphs and videos—is processed faster and remembered for longer. You should design safety signs accordingly and use images to illustrate your safety message.

Yodeck’s digital sign templates make creating visual safety sign content easy. Simple images, drag-and-drop functionality , and a wide range of ready-to-use templates ensure safety signs can be created and displayed within minutes.

Deploy the appropriate colors

As mentioned, both the UK and the USA have specific guidance on the colors to be used with different categories of safety signs.

Let this standardization work for you. Staff is already used to seeing hazard warnings in black with yellow backgrounds or fire points as white images on red backgrounds.

Place signs where they can be seen

It sounds simple, but placing signs around your factory floor can be more difficult than it seems. Movable step ladders, factory machines, and busy colleagues can easily hide safety signs with the daily activities in a workplace.

Placing signs a little higher stops them from becoming obscured and ensures everyone can see the messages displayed. Smaller, location-specific safety signs, such as those used for certain machines, should also be fixed to the machine at eye-level height—where they’re unlikely to be hidden by everyday activities.

Be flexible and see what works

Signs of all kinds need to be understood and adhered to by staff. The only way to ensure this is with training, supervision, and feedback.

If the signs aren’t working, a change to their format or message may help. At the same time, brief staff regularly on safety protocol to back up the signed messages shown around your manufacturing facility. As safety procedures change, signs need to change with them. Out-of-date signs can be just as dangerous as no signs at all.

Digital signs are easy to update and rotating safety messages or safety symbols on digital screens can make them more memorable and easier to understand—particularly if more than one safety message is relevant to a specific area of your operation.

Why Digital Signage for Safety Messages Works So Well

Keep employees safe and save both time and money with Yodeck’s digital signage. Thanks to digital displays, it’s easy and quick to make changes to factory signage and comply with regulations, and you’ll ensure all staff is clear on what they need to do.

Yodeck has a variety of digital signage options that meet the needs of manufacturers. If you’re looking for a convenient and cost-efficient way to increase workplace safety in your factory, Yodeck is a great place to start.

Explore Yodeck’s digital signage options for manufacturers today, and prioritize your team’s safety.