In this complete breakdown of modern warehouse signage, we will cover its role in warehouse management, the benefits of its proper deployment, and the current optimization strategies.

The basics

Warehouse signage is more than just a collection of placards, posters, and symbols. It is a navigation, safety, and operational tool of utmost importance for the modern labyrinthine facilities of industrial and logistics businesses.

The warehouse environment today is becoming the central hub of logistics and supply chains, and this evolution creates a clear need for effective signage.

Why is warehouse signage important?

Warehouse sign occupies a double role in the storage and logistics industry; it is both required (as such by organizations like OSHA) and also a powerful efficiency engine.

It is most commonly understood as having a key role in maintaining easy warehouse navigation and the flow of information within a busy storage environment. When properly implemented, such a signage system is a critical factor in guaranteeing compliance with sign regulations, reducing workplace injuries, and enhancing operational efficiency.

Moreover, as new technologies become smarter and more accessible, many innovators have enabled and pursued digital solutions in warehouse management that range from barcode signs to digital warehouse aisle signs. This new class of applications allows for more sophisticated operations and precise internal communication in a number of ways.

What is digital warehouse signage?

Digital warehouse signage is the application of digital signage software in warehouses and other storage locations. It comprises a crucial advancement in the way company information is relayed to the warehouse workers.

Unlike traditional static floor signs and aisle markers, digital signs are dynamic and can be updated in real-time. This, in turn, allows changes in inventory levels, safety warnings, and operational instructions to be communicated instantly and precisely to visitors and workers. It also brings new capabilities for creating, editing, and centrally managing information on the content management level. Put simply, digital warehouse displays greatly enhance the way company information flows within a given facility or even across multiple locations.

Digital signs can display a variety of multimedia content, including text, video, and graphics, which can be customized to suit different zones or specific operations. Not only limited to improving productivity, the use of digital signage in warehouses fosters a safer working environment with critical information delivered directly to employees.

Utilizing a versatile tool such as a warehouse screen also unlocks additional integrations, which can be beneficial both operationally and financially. Integrating digital signs with warehouse management systems (WMS) can lead to smarter operations. A great example of this could be signs that can automatically show directions for the most efficient picking routes, provide inventory metrics and insights, or update safety warning signs based on real-time data about a building’s conditions.

This integration goes to show how digital warehouse sign is an essential tool in the digital transformation of modern warehouse safety.

Types of warehouse signs

- Aisle signs: Durable and permanent signs that enhance navigation and spatial organization.

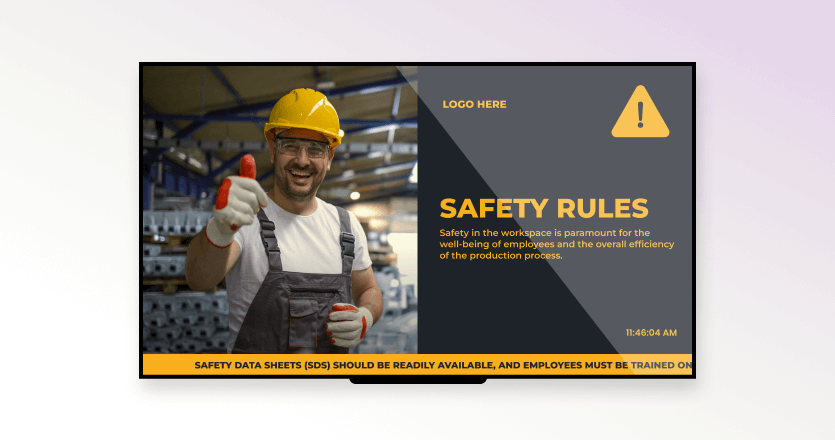

- Safety signs: Mandatory signs that mark hazardous zones, protective equipment requirements, and safe practices.

- Dock door signs: Signs that mark docking areas, doors, and elevators. Essential for improved traffic flow and safety.

- Hanging signs: Cube signs for 360-degree visibility and flat signs for walls and end-of-rack placements.

- Miscellaneous and custom warehouse signs: Signs tailored to specific needs including custom text, graphics, and colors for operational efficiency. Ideal application for digital displays that can be dynamically updated.

Features of warehouse signs

This chapter focuses on the vital layers of warehouse signs, following how they have evolved from simple floor marking to essential elements of warehouse management.

Sign visibility

Visibility is the cornerstone of effective warehouse signage. Traditional signs utilize bold colors and large fonts to catch the eye, ensuring that information is accessible even from a distance. Digital signs, on the other hand, leverage dynamic lighting and electronic displays that can change based on specific triggers or schedules. This adaptability enhances visibility under varying lighting conditions and operational states, which is crucial for maintaining a smooth workflow.

Signage compliance

Compliance with regulations such as OSHA and ANSI is non-negotiable for warehouse signage. Traditional signs are designed to meet these standards with specific colors, symbols, and placements that mitigate risks and inform safety practices. Digital signage pushes this further by allowing real-time updates and reminders for compliance needs, ensuring that the latest safety protocols are always displayed and adhered to.

Technological integration

The integration of technology in digital signs offers unprecedented control over content and its delivery. Features like IoT connectivity enable signs to interact with warehouse management systems, displaying real-time information such as inventory levels or safety alerts. This integration not only supports operational needs but also enhances safety by providing immediate updates.

Customizability

Customization is a key feature of both traditional and digital warehouse signs. Traditional signs can be tailored in terms of material, size, and graphics to fit the unique layout of a warehouse. Digital signs go a step further by allowing the creation of a custom warehouse sign that can display messages based on current events or specific operational phases, thus providing flexibility that can adapt to evolving business needs.

Operational efficiency

Ultimately, the primary goal of any signage system—be it traditional or digital—is to boost operational efficiency. Proper signage streamlines workflows by clearly marking zones, directing traffic, and aiding in the quick identification of products and locations. Digital signs add value by reducing the time needed for updates and by facilitating a more fluid movement of goods and personnel, thanks to their dynamic nature.

Benefits of an effective deployment

Regulatory compliance

Compliance with standards like OSHA and ANSI ensures that signage not only meets legal benchmarks and safety protocols but also actually supports a safe workplace culture. Both traditional and digital signs must always display fire exits, hazardous zones, and safety equipment locations to ensure a safe workplace and prevent costly violations.

Integration with warehouse management systems

The integration of signage with warehouse management systems (WMS) can be a critical efficiency enabler. Real-time information can directly improve throughput volume and inventory accuracy as long as facilities utilize digital signs to directly visualize their WMS metrics and insights on the warehouse floor. There, workers have accurate and timely data to optimize their routes and unit collection, resulting in more volume being moved smarter.

Increased productivity

Clearly marked spaces, when accounting for the sheer size of modern warehouses, can make or break productivity. Properly designed and deployed signage, including content management for digital screens, can drastically reduce the time employees spend searching for items and improve picking route efficiency. Digital signs, with their real-time updating capabilities, can guide workflows and eliminate bottlenecks. As a result, the operational output is directly boosted due to overall improved traffic flow and movement.

Enhanced safety

Signs serve as constant, silent guardians. Clearly displayed danger signs about hazards, instructions for safe warehouse operation, or an emergency sign to exit routes significantly decrease the likelihood of workplace accidents. Digital signs offer the added advantage of being able to change rapidly in response to immediate hazards or updates, providing real-time safety alerts that are hard to overlook.

Operational efficiency

Customizable signs, both traditional and digital, can be tailored to fit the unique layout and operational needs of any warehouse. Digital signage systems integrate with warehouse management software, offering dynamic location updates and instructions based on inventory levels or task priorities, thus optimizing the workflow and space usage.

Wrapping up the package

In conclusion, effective signage, both traditional and digital, plays a crucial role in enhancing regulatory compliance, visualizing warehouse management systems, boosting productivity, ensuring warehouse safety, and optimizing operational efficiency. A strategic approach to implementing a signage solution like this can transform a warehouse’s dynamics, fostering a safer, more efficient, and compliant workplace.

What you should do now

When you’re ready to take the first step in your transition, here are three ways that Yodeck can help you go greener:

- Book a demo: Our team will show you how easy it is to use Yodeck and answer all your questions.

- If you want to delve deeper into digital signage, visit our Blog and Yodeck Academy. Both are full of use cases, guides and more resources to make you an expert on Yodeck.

- Register to try Yodeck yourself today. Your first screen is forever free!